Maintenance contracts

ALGENCAL as an Installation and Repair Company of Pressure Equipment category EIP2 and ERP2, we are sufficiently qualified and approved (by the Ministry of Industry, Energy and Commerce) to offer a service of Inspections LEVEL "A" and the Regulatory Maintenance to the boilers (Watertube and Pyrotubular) according to Royal Decree 809/2021.

- Steam boilers

- Boilers with Biomass fuel.

- Hot water boilers

- Satellite Plants of G.N.L.

- Thermal Oil Boilers.

Maintenance

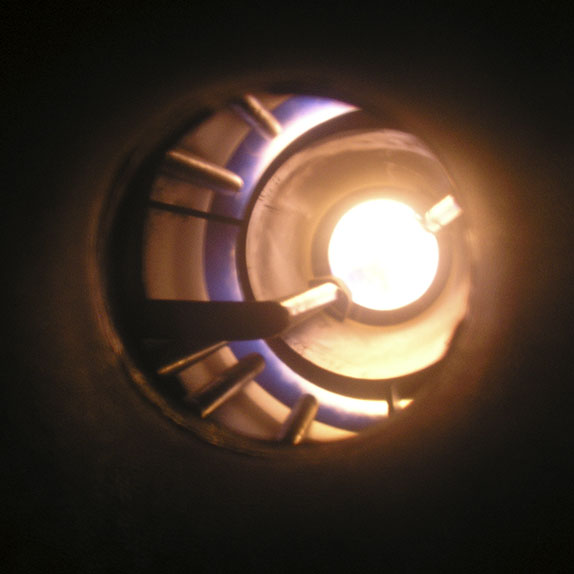

Maintenance of the Boiler/Burner set of any type of manufacturer and fuel (Natural Gas, Propane, Biogas, Diesel, Fuel oil, Special fuels: Sulfur, coal, Biomass, etc.).

During maintenance, all parts of the boiler/burner assembly are disassembled, cleaned, visually inspected and the operation of all elements is checked, informing the customer of any defective element or mechanism, and if possible to solve it, replacing all seals and gaskets, ensuring uninterrupted operation of the equipment.

The combustion is regulated and adjusted to ensure the best values of emissions to the atmosphere and the highest performance with the consequent energy and operating cost savings.

The excellence of our maintenance generates savings in operating costs and extends the useful life of the equipment.

In addition to preventive maintenance, we have a team of qualified technicians to perform corrective maintenance and technical assistance services for 24-hour breakdown attention.

Boiler and burner upgrades

Technical improvements and modernizations are made to boilers and burners with several years of manufacturing, installing PLC controls, new instrumentation can be installed for monitoring and measuring steam flow rates, feed water, natural gas consumption, level controls, for continuous monitoring of the equipment with the possibility of communicating with SCADA system.

Burner modernization is carried out by converting the mechanical modulation into electronic modulation by installing new LAMTEC controllers, with the possibility of installing continuous control of Oxygen and COe for combustion optimization.

Regulatory Maintenance

Regulatory Maintenance of Pressure Equipment, Gas Appliances, Liquid Petroleum Products on an annual, semi-annual, quarterly, monthly basis according to the corresponding Regulations and Standards.